RFID Basics

Here's common terminology, how RFID technology works, the overall workflow to implement RFID, and the benefits for suppliers and Walmart.

Common Terminology

Term | Definition / Description |

ARC | The Auburn University standard that ensures RFID tags are able to meet or exceed the levels of performance and quality necessary to provide benefit to the end user in a consistent and cost-effective manner. |

Auburn University RFID Lab | A research institute focusing on the business case and technical implementation of RFID and other emerging technologies in retail, aviation, supply chain, and manufacturing. |

EAS Tag | Electronic Article Surveillance (EAS) is a type of system used to prevent shoplifting. RFID cannot overlap with the EAS tag, but both can be used on the same item. |

Encoding | The process of encoding the EPC in the chip of an RFID tag. All EPCs must be encoded using the SGTIN-96 format.  You have two options for encoding RFID:

Learn more about these options in How to Implement RFID. |

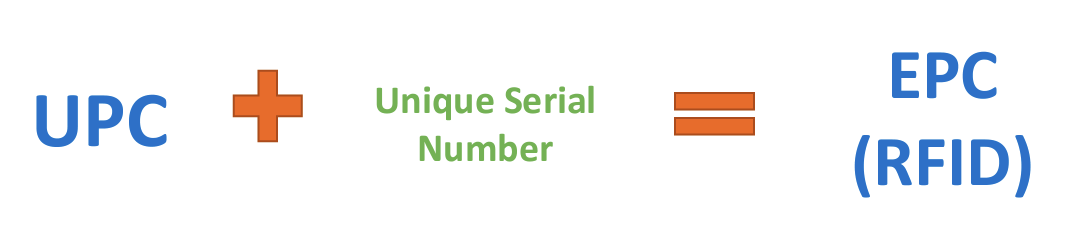

EPC Logo | EPC stands for 'Electronic Product Code', which consists of the GTIN + a unique serial number. The EPC symbol is an industry standard to inform the customer and store associates that the tag/packaging contains RFID.  |

GS1 (Global Standards 1) | An information standards organization to help organizations of all sizes uniquely and consistently identify products, assets, shipments, and physical locations throughout the global supply chain while also enabling trading partners to exchange information critical to their businesses. |

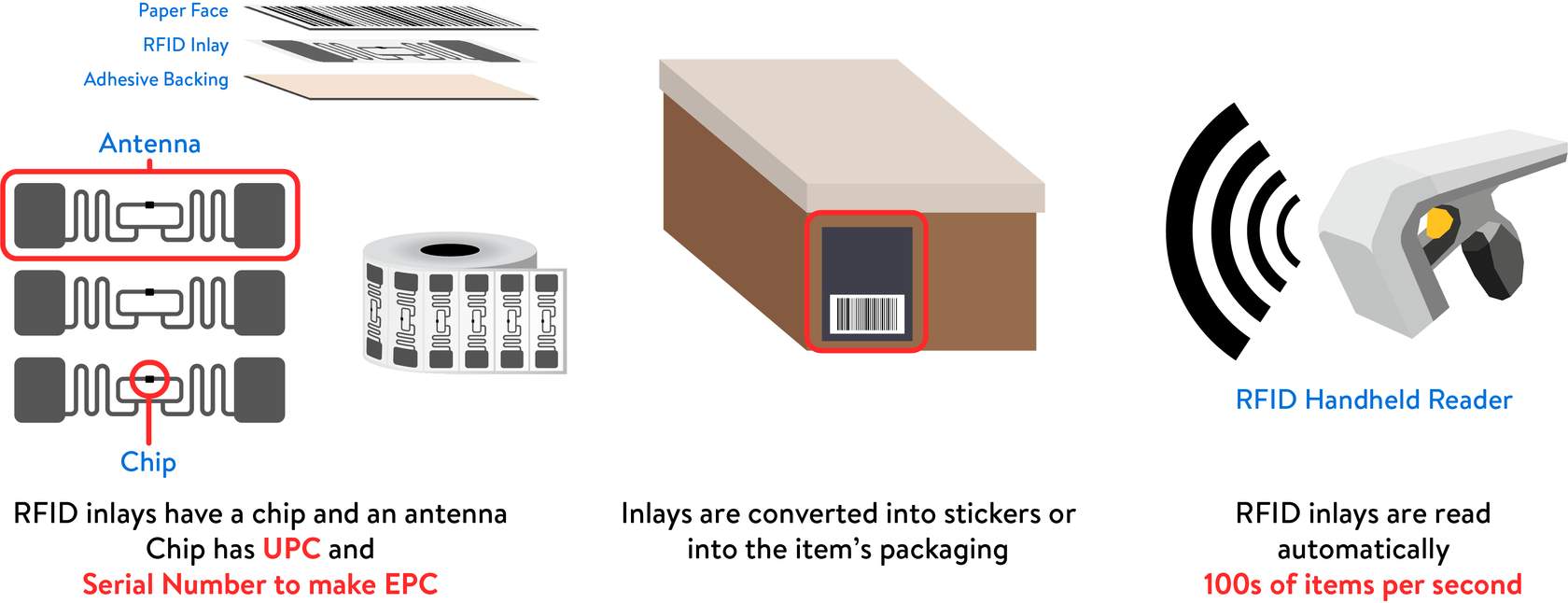

Inlay Manufacturer | A company that produces RFID inlays, which consist of the chip and antenna portions of the RFID tag. Approved inlays are converted into tags by packaging providers. |

Inlay Size | Based on the Walmart inlay spec. For the best performance, use the largest inlay size available that fits your packaging. |

Inlay Spec | Walmart has a set of inlay specifications that are performance-approved from the Auburn University RFID Lab. Refer to the chart in the RFID Playbook or on the Auburn University RFID Lab’s website to see what spec has been assigned to each category. You can only use an approved inlay from an item’s associated inlay list. |

Packaging Provider or Service Bureau | There is a list of packaging providers that have supplied packaging for other RFID Programs and could help with your RFID packaging needs for Walmart. All packaging providers will need to source an Auburn University ARC-approved inlay. |

RFID | Stands for 'Radio Frequency Identification' – a technology that uses electromagnetic fields to easily identify and track tags attached to objects. |

RFID Inlay / Tag | A combination of a specific chip and antenna design. |

RFID Playbook | A guide that Walmart has created to help you, your technical partners, and your supply chain/manufacturing team through the RFID implementation process. |

Serialization | Unique serialization is required for each item with an RFID tag (see "Encoding" above). Please ensure unique serialization is managed when using multiple packaging providers for the same SKU. Learn more here. |

SGTIN-96 | The GS1 standard for a 96-bit RFID tag encoded with a GTIN and unique serial number (i.e., the EPC). Go to https://www.gs1.org/standard/tds for more details. |

What Is RFID?

RFID stands for radio frequency identification, which uses electromagnetic fields to easily identify and track tags attached to objects. RFID tags can be read easily through cardboard, plastic, and even concrete walls. Some product materials – like metals, foils, liquids, or glass – require additional considerations through Auburn University, but they can also work with RFID. A store associate uses an RFID reader to quickly scan for RFID tags.

How Does RFID Benefit My Business?

RFID has been proven to accurately count and manage inventory and business processes. Consider utilizing RFID in your own business for: Outbound validation, inbound audits, claims compliance, invoice accuracy, cycle counting, shrink reduction, DC and cross-dock optimization, QA and QC processes, internal serialization, and receiving automation. Please see the list of Business Use Cases in Auburn University's White Paper for a more in-depth study on how your business can benefit from RFID.

How Does RFID Work?

There are two components to RFID technology:

- An RFID tag with an integrated chip and antenna (aka an RFID inlay) that goes on each product

- An RFID reader that store associates use to quickly scan products for RFID tags

RFID at Walmart

Before RFID, store associates had to count items individually. This took a lot of time and effort, which impacted inventory accuracy and the customer experience in stores and online.

Implement of RFID - Workflow

Walmart is following all industry standards set forth by the GS1 RFID serialized encoding standard, Auburn University RFID Lab tag placement standards, and ARC inlay standards. All tagging requirements must meet these standards prior to arriving in our U.S. stores. This includes all national, proprietary, supplier, and private brands within the scope of the RFID program.

The following is an outline of how RFID will be implemented for all suppliers in scope:

- If your items are in scope, you should have received the onboarding communication that RFID needs to be implemented for your products/departments. If you have not received this email but believe you should have, please reach out to the RFID team at WalmartRFID@walmart.com. Remember that your tagged products must arrive in stores no later than the date provided in this onboarding communication.

- By this time, you should also have attended a kickoff meeting hosted by Walmart and Auburn University RFID Lab or viewed a recording of a kickoff meeting provided by the Walmart RFID team. We recommended bringing your technical partners.

- Complete the self-paced RFID training course in Supplier Academy.

- Refer to the help articles, playbook, tag placement guide, and Submission Guide for details and support as you work with your technical partners and supply chain/manufacturing team to implement RFID.

- You will need to submit a list of all supplied items along with samples of your fully encoded RFID tags to the Auburn University RFID Lab for performance and accuracy testing prior to bulk production.

Complete the Submission Form through the Auburn RFID Submission page provided later in this training. This includes:- Uploading at least 6 high-quality photos and 1 video of the one representative sample item that clearly shows the dimensions and composition of the product and packaging in relation to the location of the RFID tag.

Refer to the checklist on the Submission Form before sending your samples to the lab. - You will receive an online confirmation as well as a confirmation email from Auburn University RFID Lab with your submission number, specific info about next steps, and contact info. Print and mail a copy of the PDF confirmation with your 5 RFID tag samples (no product or packaging) to the lab. All 5 samples should be the same UPC and must be submitted for every group of like items. The lab will contact you on the success/failure of your submission once your sample has been tested. Validation will be completed within 10 business days of delivery.Please work with your current packaging resource(s) to create these samples.

- Once your submission has been approved, work with your technical partners and supply chain/manufacturing team to make sure all of your products have RFID tags.We recommend working with a minimum of two RFID packaging resources and having both of their samples approved by Auburn.

Benefits for Suppliers and Walmart

Implementing RFID is a joint investment. Suppliers invest in the tagging while Walmart invests in the hardware, software, and training/labor for our associates. We've seen how RFID helps better manage inventory, reduce out of stocks, and provide a better shopping experience. By working together on this program, we can lower the overall costs of operation and keep providing everyday low prices for our customers.